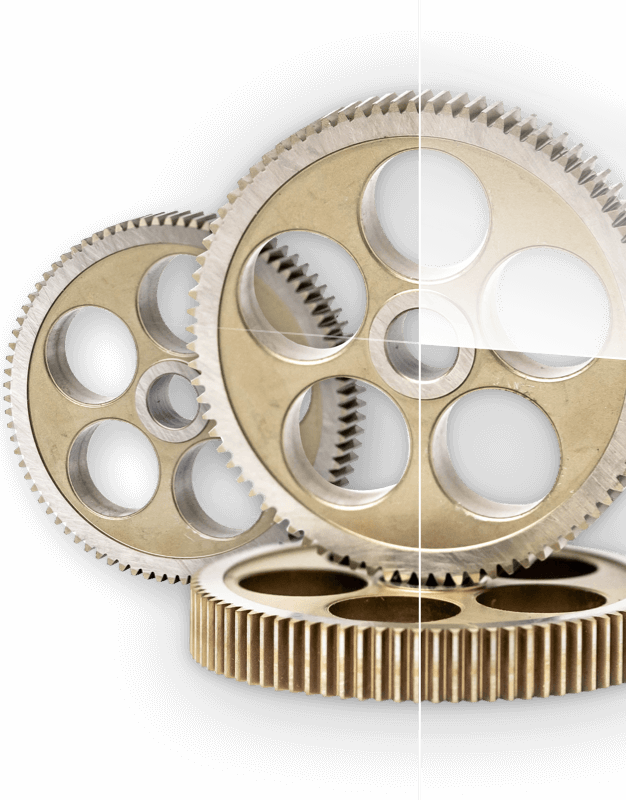

Powder Metal Manufacturing - Sintered Metal Products

Learn more about the Powder Metal Manufacturing process:

Powdered & Sintered Metal Products

Powder Metallurgy Workshops (PM101)

Understanding Sintered Metals – Customized for Your Company

Atlas's Powder Metallurgy educational workshops are customized for each company's needs. Your team can explore powder metallurgy, understand the opportunities to advance current powdered metal designs, or evaluate parts for potential conversion from conventional machining to powdered metal manufacturing.

For more information on a complimentary workshop custom designed for your company, click here or contact Joe Pfingstler at (814) 299-7202

Atlas: Your Powdered Metal Product Partner

Design Optimization

Atlas Pressed Metals has an engineering group with extensive powdered metal experience.

Atlas has assisted current customers with the conversion of purchased parts from other processes to powdered metals or the combination of several parts within an assembly to one powdered metal part. Each of these situations resulted in significant cost savings.

Design

Solutions Engineering

We employ a team of engineering and metallurgical professionals that understands the intricacies of the process and materials.

Atlas Pressed Metals’ team provides service on the front end in the form of product development, design assistance, and material selection. This is especially advantageous with multi-level designs with tight dimensional tolerances and complex geometries.

Metallurgy Lab Testing

With our own in-house, state-of-the-art metallurgy lab, Atlas Pressed Metals offers Ph.D.-level services to increase quality control and reduce turn-around time.

As a leading precision powdered metal parts manufacturer, our staff conducts full mechanical and metallurgical evaluations during the PPAP process and throughout the entire manufacturing process. Strength, density, hardness and porosity determinations are all conducted according to Metal Powder Industry Federation standards. Images and data on results are sent to our customers in a convenient, quick email.

Lab

Sintered Metal & Powdered Metal Finishing

Secondary Operations at Atlas are value-added processes available to PM manufactured components.

Our capabilities include repressing, impregnation, infiltration, heat treating, machining, & finishing.

Operations

Powder Metallurgy

Resource Hub

See All Powder Metallurgy Resources

Take a look at these educational powder metallurgy resources:

Materials

We have a wealth of in-house equipment and materials to service a variety of projects

Atlas Pressed Metals offers top-of-the-line materials for all precision sintered metal products.