The Materials Advantage at Atlas

![]()

From sustainable material solutions to conversion opportunities, Atlas can help you stay ahead of evolving customer and market needs:

Engineering Expertise

Lean on our deep understanding of the powder metallurgy (PM) process to get the best results within your budget. As a true manufacturing partner, we’ll explain how your chosen material will impact price, performance, and the overall assembly.

Variety & Availability

Different parts, products, and industries call for different solutions. Atlas’ vast selection of powder metal materials can optimize your new or existing PM or non-PM part for:

- Strength

- Durability

- Magnetic Response

- Cost Reduction

We maintain a commitment to a 100% on-time delivery rate thanks to our partnerships with top powder suppliers.

Materials R&D

Our advanced in-house metallurgical lab keeps you ahead of the competition with cutting-edge technology.

There remains a vast, untapped potential in sintered metals. Our materials team offers extensive testing and development of high-performance alloys.

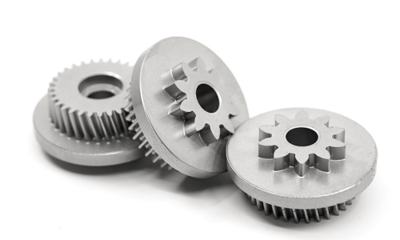

Explore Our Powder Metal Materials

![]()

Stainless Steel Materials

Stainless steel powder metal parts bring a unique blend of strength, durability, and appearance.

- 300 Series Alloy – High physical & corrosion resistance.

- 400 Series Alloy – Great magnetic properties & response to heat treatment.

Iron & Soft Magnetic Materials

Ferritic powders excel in DC electric applications where magnetic performance is paramount. Our pure iron and iron-phosphorus materials stand out for their structural integrity.

- Iron– Unalloyed, pure material for light-load structural applications

- Iron-Phosphorus – High magnetic response in DC fields

Copper-Based Materials

Steel Materials

Steel-based metal parts offer a balance of strength, toughness, and cost-efficiency. With excellent mechanical properties, our steel powder materials can support assemblies that must perform under stress and strain.

- Iron-Copper – Medium-strength structural applications.

- Carbon – Light-load structural applications.

- Iron-Nickel – Heat-treatable structural parts.

- Prealloyed Steel – High-performance parts that require heat treatment.

- Low-Alloy Steel – Medium-to-high-density applications. Can be heat-treated. High hardenability.

- Sinter-Hardened Steel – High-strength and wear-resistant parts.

- Diffusion-Alloyed Steel – Medium-to-high-strength structural products.

- Copper-Infiltrated Steel – Medium-pressure hydraulics. Improves plating surface & machinability.

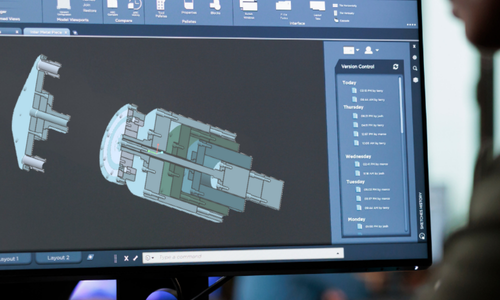

Other Powdered Metal Manufacturing Services

![]()

The results are quicker and better when your entire component production process is under one roof. Atlas Pressed Metals is a full-service provider of:

.png)

Custom Engineering Capabilities

We have the capabilities and capacity to engineer components ranging in size from 0.68g (0.0015 lbs) to 6800g (15 lbs). Our designs typically fall into three categories:

- Structural Components

- Gears

- Bearings

Comprehensive Design Support

Atlas has an in-house team of engineering, production, quality, and metallurgical experts to support your design needs. From initial design to final product, we offer full-service assistance and support to optimize your part for manufacturing and assembly. We're here to assist with:

- New Part Design

- Part Design Optimizations

- Powder Metal Conversions

Materials Expertise

We manufacture components using pressed (powdered) metals including:

- Iron

- Sinter-Hardened Steel

- Stainless Steel

- Copper and Copper Alloys

Our metallurgical team will help you choose the right material.

Need a Solution?

Ask Us a Question

Contact Information

Mailing Address

125 Tom Mix Dr.

P.O. Box P

DuBois, PA 15801

USA

Phone

Fax

Testimonial

"Our Engineering team works directly with Atlas Pressed Metals to achieve our company goals. Atlas is always very helpful, gives us on-time delivery and the sales reps are always willing to research to get answers for our needs.”

- Amanda S., Associate Buyer | Healthcare Industry

.png?width=300&name=Webpage%20Background%20(4).png)