What is a Powder Metal Gear?

![]()

A powder metal gear is a type of gear manufactured using powder metallurgy. This process involves compacting powdered metal into a desired shape using precision tooling and compaction presses, followed by sintering, which is a heat treatment that fuses the particles together. Powder metal gears can be produced to near-net-shape or even net shape, meaning they require little to no secondary machining operations. This method is efficient and cost-effective, especially for complex gear geometries, and results in faster production times compared to traditional machining methods.

.png?width=400&height=400&name=Website%20Images%20500%20X%20500%20(55).png)

Key Benefits of Powder Metal Gears

![]()

- Tight Tolerances and Dimensional Accuracy: Powder metallurgy allows for tight tolerances, dimensional accuracy, and consistency, accommodating all production volume requirements.

- Cost-Effectiveness: High material utilization makes powdered metal a cost-effective choice. Producing components to tight tolerances often eliminates or reduces the need for additional operations, saving both time and costs.

- Eco-Friendly Process: Powdered metal is a green process with low energy usage and minimal scrap, making it more economical than standard machining, casting, or other metal-forming technologies.

- Optimized Performance: Material selection for gears allows for optimization of the component’s performance for its intended application with little variation in the manufacturing process.

Industries and Applications for PM Gears

![]()

Industries Using Powdered Metal Manufacturing for Gears:

- Appliances

- Automotive

- Medical Device

- Power Tools & Equipment

- Lawn and Garden

Types of Gears Suitable for Powder Metallurgy:

- Spur

- Helical

- Bevel / Spiral Bevel

- Pinion

- Combinations

- Rack

Additional Benefits of Using PM for Gears

![]()

Powder Materials for Structural Applications

![]()

Common Materials for Gear Production:

- Iron-Nickel and Nickel Steel: Admixtures of elemental iron, nickel, and graphite (when required) powders. These materials provide heat-treatable structural parts with strength, wear resistance, and impact properties.

- Prealloyed Steel: Developed from pre-alloyed low-alloy steel powders with nickel, molybdenum, manganese, and chromium as alloying elements. Used for components requiring heat treatment to increase strength and wear resistance.

- Hybrid Low-Alloy Steel and Diffusion-Alloyed Steel: Other powders used for specific applications.

Sinter Hardened Steel:

- Ideal for components requiring high strength, wear resistance, and tight tolerances.

- Hardened during the sintering process, providing improved dimensional control, cleanliness, and reduced processing steps compared to other heat treatment options.

- Note: Sinter-hardened materials are not easily machined.

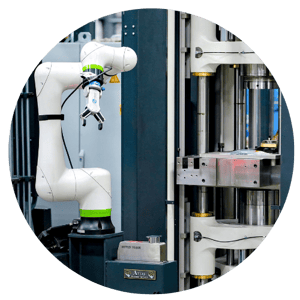

Powder Metal Process

![]()

.png?width=300&name=Website%20Images%20500%20X%20500%20(49).png)

Collaborative review of your new part design or an evaluation of a potential conversion to powder metal for an existing part

Selecting the best powder or powder blend for durability, reliability, and accuracy

Compacting the metal powder to precise specifications under controlled pressure

Heating or "Sintering" to create a permanent form

Powder Metal Design Specifications

![]()

At Atlas, our team of skilled engineers brings extensive industry experience and knowledge to guide you through every stage of your structural component requirements. From weight to shape, our flexibility is our expertise. We design and manufacture components with the following specifications:

- Weight: 453.59 grams (1 lb) to 1360.78 grams (3 lbs)

- Diameter: 0.32 cm (0.125”) to 12.7 cm (5”)

- Length: 0.635 cm (0.25”) to 3.81 cm (1.5”)

- Shapes: Structural, spherical, flanged

Our advanced molding, sintering, and sizing capabilities, combined with a robust quality metric system, enable us to handle parts of all sizes and complexities. Powdered metallurgy, an economical and eco-friendly manufacturing option, minimizes material waste and reduces costs.

.png?width=500&height=300&name=Website%20Images%20500%20X%20300%20(4).png)

Need a Solution?

Ask Us a Question

Contact Information

Mailing Address

125 Tom Mix Dr.

P.O. Box P

DuBois, PA 15801

USA

Phone

Fax

Testimonial

"Our Engineering team works directly with Atlas Pressed Metals to achieve our company goals. Atlas is always very helpful, gives us on-time delivery and the sales reps are always willing to research to get answers for our needs.”

- Amanda S., Associate Buyer | Healthcare Industry

.png?width=300&name=Webpage%20Background%20(4).png)