.png?width=300&name=Webpage%20Headers%20(25).png)

Metallurgical Lab & Testing Services at Atlas Pressed Metals

![]()

The metallurgy lab at Atlas Pressed Metals provides detailed testing and analysis for powder metallurgy parts. Our team utilizes MPIF and ASTM standards to verify the strength, hardness, porosity, and other critical properties.

Whether you need a one-time evaluation or ongoing testing support, our metallurgical testing and analysis services are available to customers as part of our commitment to ongoing quality assurance.

Specimen Preparation

Our experienced team excels in the precise handling of metallographic sample preparation, ensuring high-quality results through meticulous processes. We specialize in:

- Sectioning

- Mounting

- Polishing

-1.png?width=500&height=300&name=Website%20Images%20500%20X%20300%20(1)-1.png)

Metallurgical Lab Testing

We conduct thorough microstructural evaluations using our 50x to 1000x optical microscope and Scanning Electron Microscope (SEM). These evaluations help assess the integrity of welds, joints, coatings, and plating, as well as detect inclusions and total carbon content. Our SEM is also instrumental in failure analysis, examining fracture surfaces, corrosion, wear, and contamination.

Mechanical Evaluations

We perform comprehensive mechanical evaluations during PPAP, for process control, and throughout the part manufacturing lifecycle. Tests for strength, density, hardness, and porosity are conducted according to Metal Powder Industries Federation standards.

Metallurgical Lab Information

![]()

General Capabilities

In our metallurgy lab, we look closely at materials, part performance, and coatings to make sure they meet expectations. Capabilities include:

- Material testing and microstructure analysis

- Scanning Electron Microscopy (SEM) equipped with EDS

- Strength testing (Tensile and Crush)

- Density, porosity, and hardness measurements

- Corrosion and torque testing

- Dimensional change evaluations

These services provide the data you need to confirm your parts meet design intent, regulatory requirements, and end-use expectations.

.png?width=490&height=490&name=Website%20Images%20500%20X%20500%20(35).png)

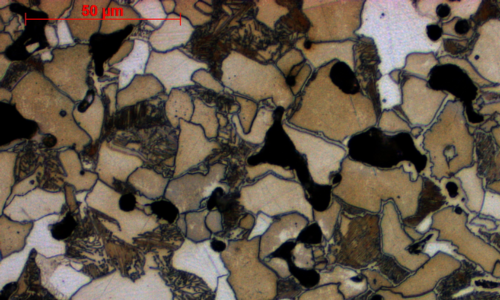

Light optical microscope (LOM) image at 500x magnification of copper infiltrated steel alloy material. Image by Atlas Pressed Metals.

Material Testing & Microstructure

![]()

Understanding the structure of a component at the microscopic level is crucial for predicting its performance.

- Optical microscopy allows us to evaluate grain size, porosity, and coatings.

- SEM with Energy-Dispersive Spectroscopy (EDS) enables the analysis of chemical composition and defect identification.

These results help pinpoint failure causes and confirm that parts are built to last.

Strength Testing

Strength testing measures how well a component resists the forces it’s designed to carry.

- Tensile Testing (MPIF Standard 10): Measures tensile properties of powder metallurgy materials.

- Crush Testing: Evaluates part performance under compressive loads.

Our strength testing processes align with ASTM and MPIF standards, giving you reliable data you can trust.

Density & Porosity Testing

Density and porosity play a big role in how powder metal parts perform.

- MPIF Standard 42: Density of compacted or sintered PM products.

- MPIF Standard 57: Oil content, surface-connected porosity, and oil-impregnation efficiency.

By measuring density and porosity, we help ensure components maintain consistent performance in demanding conditions.

Hardness & Tensile Properties

Mechanical properties are what make a part dependable.

- Microindentation Hardness (MPIF Standard 51): Evaluates localized hardness in powder metallurgy materials.

- Tensile Properties (MPIF Standard 10): Confirms parts meet strength requirements for their intended applications.

These methods provide manufacturers with assurance that their powder metallurgy products can withstand everyday wear and tear.

Radial Crush & Torque Testing

Powder metallurgy components often function in high-stress applications.

- Radial Crush Strength (MPIF Standard 55): Determines resistance to radial forces, commonly used for bushings and cylindrical parts.

- Torque Testing: Conducted per customer specifications to measure torque capacity in real-world conditions.

This testing ensures parts won’t fail under torsional or compressive stress.

Corrosion Resistance

For components exposed to moisture or harsh environments, corrosion testing is essential.

- ASTM Standard B895: Evaluates corrosion resistance of stainless steel PM parts through immersion in sodium chloride solution.

Our corrosion resistance testing provides confidence in long-term durability for automotive, appliance, and industrial applications.

Dimensional Change Characteristics

Dimensional stability is crucial for assemblies requiring tight tolerances.

- Dimensional Change Testing: Performed to customer requirements, evaluating how parts change during processing or under load.

This data ensures parts consistently fit and function as intended.

.png)

Why Metallurgy Testing Matters

![]()

Rigorous testing is essential to quality assurance in powder metallurgy. At Atlas Pressed Metals, our fully equipped metallurgical lab supports our customers by helping to:

- Validate that parts meet MPIF and ASTM standards.

- Detect defects before they impact performance.

- Optimize coatings and materials for specific environments.

- Ensure compliance with customer and industry requirements.

Reliable metallurgy analysis doesn’t just confirm part quality; it also protects your brand reputation and ensures end-user satisfaction.

Industries Served

Atlas Pressed Metals provides metallurgical testing for a wide range of industries, including:

- Appliances: Durable, long-lasting parts for high-use products.

- Medical Devices: Reliable powder metallurgy solutions in healthcare.

- Industrial Machinery: Heavy-duty components for demanding environments.

- Automotive: Gears, bushings, and precision components.

Our lab ensures every part we produce can perform reliably in its intended application.

Testing Standards

We adhere to globally recognized testing standards, including:

- MPIF Standards: 10, 42, 51, 55, 57

- ASTM Standards: B895

- Customer-Specified Methods: Torque and dimensional change testing

Following these standards makes sure our results line up with industry benchmarks.

.png?width=300&name=Webpage%20Background%20(4).png)

Partner With Atlas Pressed Metals for Metallurgy Testing

Ensure your powder metallurgy parts meet demanding standards with the help of Atlas Pressed Metals’ advanced metallurgy testing facility. Our expert team delivers fast and accurate results, so you can move forward with confidence.

Contact us today to discuss your project and learn how our metallurgical lab can support your testing needs.

Need a Solution?

Ask Us a Question

Contact Information

Mailing Address

125 Tom Mix Dr.

P.O. Box P

DuBois, PA 15801

USA

Phone

Fax

Testimonial

"Our Engineering team works directly with Atlas Pressed Metals to achieve our company goals. Atlas is always very helpful, gives us on-time delivery and the sales reps are always willing to research to get answers for our needs.”

- Amanda S., Associate Buyer | Healthcare Industry